ABC-RRS Analysis: the tool to decide whether to use MRP or Kanban

Applying a PULL logic in a Lean perspective with Kanban, or maintaining a traditional PUSH system based on MRP, is not a decision that can be made “by gut feeling”.

An objective and replicable criterion is needed to analyze materials and determine which approach is most suitable based on their characteristics.

The ABC-RRS matrix, integrated into the methodology and among the tools used by the KanbanRocket team, was created precisely to meet this need.

Data required for proper analysis

To correctly perform the ABC-RRS analysis, at least two key elements must be collected:

- Detailed consumption data for materials, including code, date, and quantity.

- Unit value of the material (average cost, last purchase cost, or sales price).

The analysis can be applied to three distinct areas, each of which must be evaluated separately:

- Purchase codes

- Production codes

- Sales codes

It is important to use a significant time horizon, such as a rolling year, to avoid distortions caused by seasonality or temporary peaks.

The two dimensions of the analysis: ABC and RRS

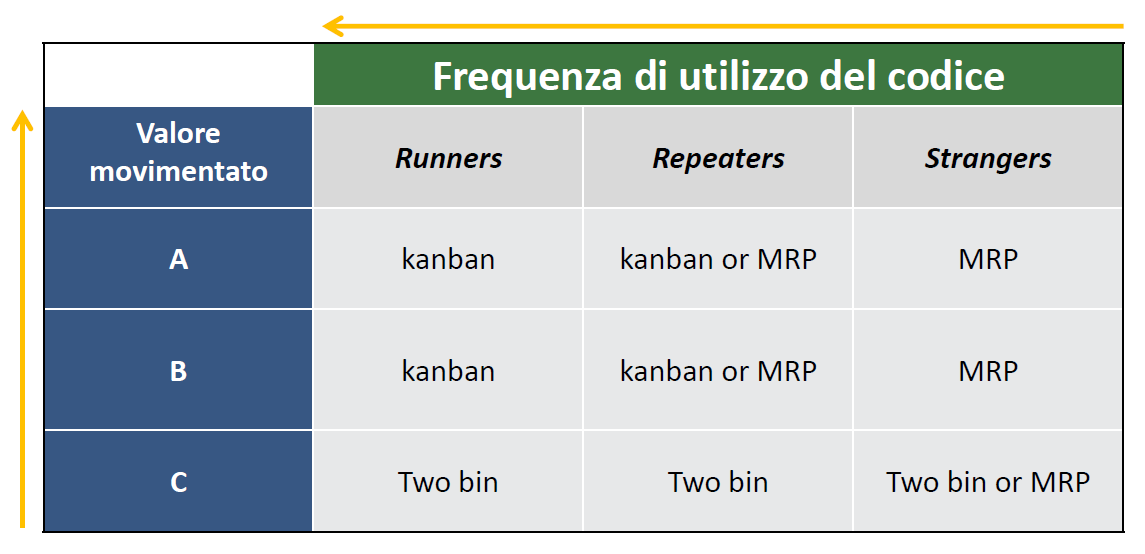

The ABC-RRS matrix combines two distinct analyses:

-

ABC Analysis (Value)

- A: codes that generate 80% of total consumption value.

- B: codes that generate the next 15%.

- C: codes with marginal weight, equal to the remaining 5%.

This classification makes it possible to identify the most economically important codes.

The ABC classification reflects the Pareto principle, where 20% of the codes should account for 80% of consumption value.

Thus, class A codes should represent about 20% of the total to be aligned with Pareto.

Note: Value-based classification is not the only option. An ABC analysis by quantity could also be performed, but in this case, special attention must be paid to units of measure to ensure consistency.

-

RRS Analysis (Frequency)

Based on the number of weeks in which the code was actually consumed:

- Runner: frequent consumption, at least once per week.

- Repeater: at least once every four weeks.

- Stranger: sporadic consumption (less than once every four weeks).

Thresholds must be adjusted depending on the sector and production/logistics context.

-

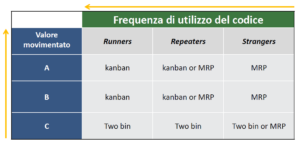

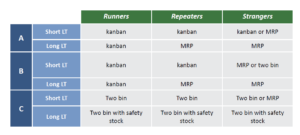

Crossing the analyses: the ABC-RRS matrix

The true value of this methodology emerges when the two classifications are combined.

For example:

- An A-Runner is a high-value, frequently consumed code: ideal for PULL management with Kanban, with short lead times and continuous replenishment.

- A C-Stranger is a low-value, sporadically consumed code: best managed with PUSH logic, via MRP planning or spot purchases.

The matrix can be further enriched by integrating the Lead Time dimension, modifying it as follows:

With the ABC-RRS matrix, companies obtain a complete map of where to apply Kanban and where to maintain traditional MRP management, avoiding mistakes such as:

- Implementing Kanban on codes that are complex to manage, with non-constant consumption and long lead times.

- Planning with MRP for items with regular consumption and short lead times, resulting in lost efficiency.

The KanbanRocket Formula

In the KanbanRocket Formula, this analysis is a fundamental step.

Once the perimeter of materials to be managed in PULL mode is defined, the process can continue with Kanban card sizing, choosing between Pure, Lot, or Signal Kanban, and implementing a sustainable and automated e-Kanban system with KanbanRocket.

comments