Astolfi 1963: Triangular Kanban for a Streamlined Supply Chain

Reading time: 3 minutes

Astolfi 1963 is an Italian company with a long-standing tradition in the production of high-quality mattresses and bed systems. Founded by grandfather Pietro and carried forward by his son Moreno and grandson Omar, the company has always focused on craftsmanship and attention to detail.

For three generations, Astolfi 1963 has been committed to quality and customer well-being, thanks to a cross-functional team of designers, carpenters, tailors, and artisans working in perfect synergy to excellently manage and improve the design, development, production, and assembly processes of its products.

Recently, Astolfi became part of the Tomasella network, a major player in the furniture industry, thus strengthening its market position and opening new growth opportunities.

In 2021, Astolfi embarked on a lean and digital transformation journey, aiming to reduce waste and improve operational efficiency. Among the various initiatives, this led to the adoption of KanbanRocket, a Supply Chain Management software for lean material flow management across purchasing, production, and logistics.

To optimize material management across the entire supply chain, in 2022 the company chose TALARYS as its technology partner to implement an e-kanban system. This solution ensures optimized inventory management and effective integration with all supply chain partners.

Types of Kanban Implemented

The implementation of KanbanRocket covered four different types of Kanban, each designed for specific internal and external flows:

-

Purchase Kanban: To manage the procurement of raw materials from key suppliers (purchase loop Kanban). The project involved collaboration and training for 11 strategic suppliers.

After testing the system on a set of pilot items, suppliers actively contributed to expanding Kanban across all relevant items. Thanks to KanbanRocket, these partners can monitor card and inventory status in real time, proactively plan deliveries, and reduce unnecessary communication. -

Production Kanban: To manage the in-house production of semi-finished products at Astolfi, improving workflows and reducing waiting times.

-

Passive Outsourcing Kanban: To coordinate processes with external subcontractors specializing in certain operations.

With this flow, Astolfi can rationally trigger external semi-finished product production, avoiding waste and overproduction. -

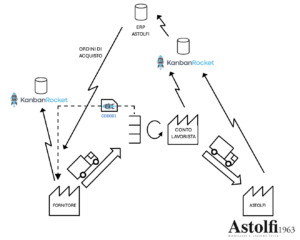

Triangular Kanban: Astolfi developed a triangular Kanban system where subcontractors themselves trigger material requests directly to Astolfi’s suppliers.

When the call is made, the materials are purchased by Astolfi but shipped directly from the suppliers to the subcontractors. This allows Astolfi to maintain strategic supplier relationships and material ownership while managing the process in the leanest and most efficient way.

Triangular Kanban in Practice

An example of a Value Stream Map implemented at Astolfi

The triangular Kanban was implemented to simplify logistics and automate inventory management at the subcontractor’s site. Thanks to KanbanRocket, the subcontractor can directly retrieve Astolfi-owned materials and trigger a purchase order from Astolfi to external suppliers.

This eliminates the need to pass through Astolfi’s central warehouse before forwarding materials to the subcontractor, streamlining logistics and reducing procurement lead times.

The collaboration among the three companies is managed in real time within the KanbanRocket platform, allowing all partners to monitor inventory levels and replenishment signals, with significant benefits in communication and error reduction.

For logistics and administrative flows, proper bidirectional ERP integrations have been implemented.

For instance, Astolfi’s ERP has been integrated with KanbanRocket to automatically generate purchase orders, setting the subcontractor’s location as the delivery address and ensuring smooth administrative management.

The adoption of the KanbanRocket system brought measurable improvements to Astolfi 1963. In the first 6 months after go-live, the e-kanban system enabled:

- 72 days average lead time reduction

- On-time deliveries improved from 78% to 97.5%

- 33% inventory reduction for triangular Kanban items

Additionally, real-time collaboration in KanbanRocket drastically reduced emails, phone calls, and other low-value activities between the three companies.

The images of the supermarkets managed with KanbanRocket speak for themselves: order, cleanliness, and visual management supporting a truly lean supply chain.

Examples of warehouse space optimization at Astolfi based on lean principles and Kanban sizing

The project developed with Astolfi 1963 demonstrates how electronic Kanban, when properly dimensioned and integrated, can become a real driver of competitiveness—even in more traditional manufacturing environments.

Thanks to KanbanRocket, Astolfi is now not only more efficient, but also more connected, responsive, and ready to face new market challenges.

comments