Electronic Kanban vs Paper Kanban: advantages and disadvantages

Kanban (看板) was born at Toyota in the 1970s as a visual tool for managing stocked materials according to pull logic.

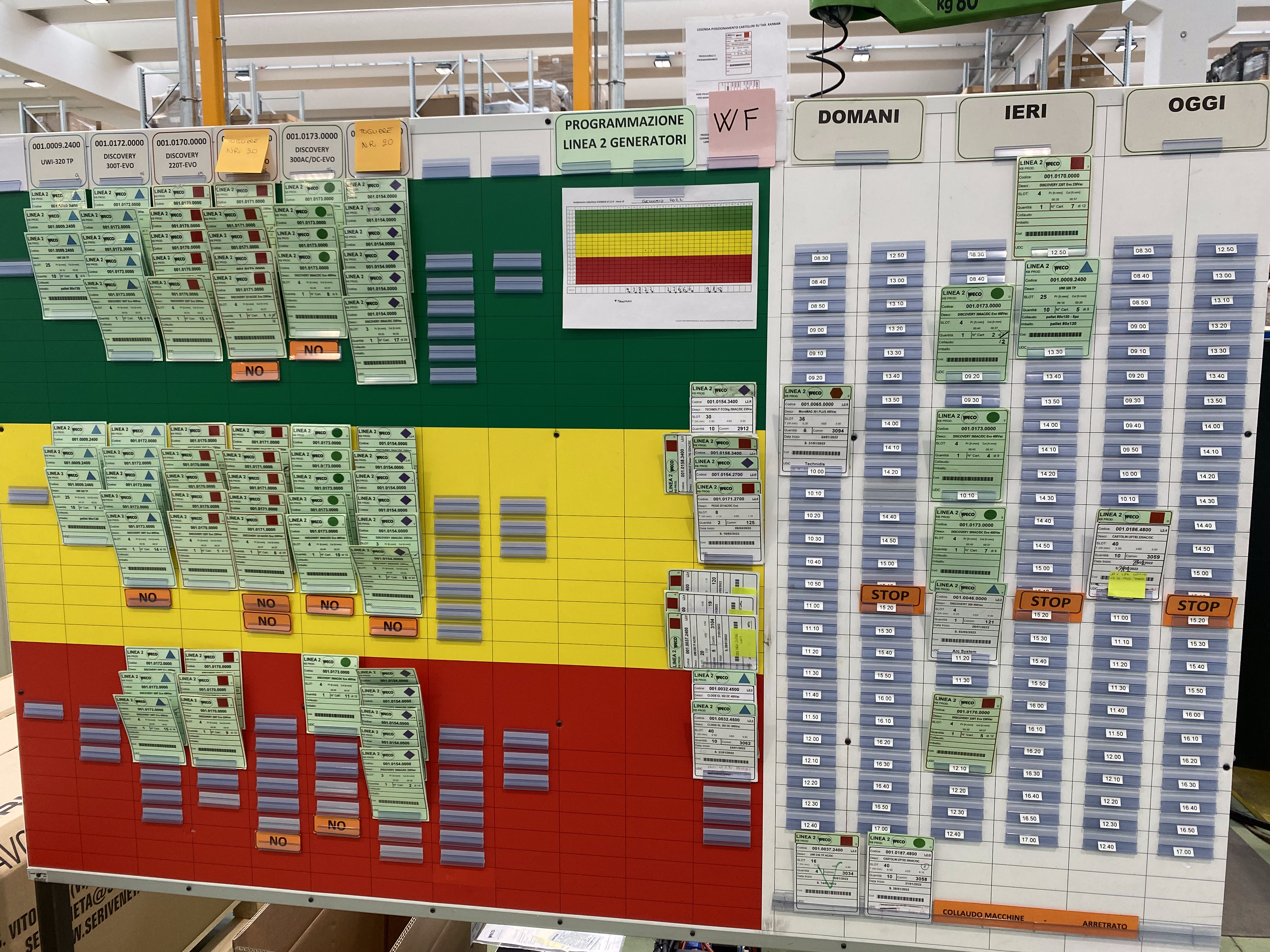

The system relied on physical, reusable cards associated with each container. When the material was consumed, the card was manually moved onto a Kanban board to signal the need for replenishment.

With digital evolution, this logic has been enhanced, giving rise to Electronic Kanban (e-Kanban or eKanban), which preserves Lean principles but amplifies their effectiveness through modern technology.

In this article, we compare traditional paper Kanban with electronic Kanban, analyzing the pros and cons of both.

Paper Kanban: features and limitations

The physical Kanban system is based on:

- Reusable cards (sometimes laminated for durability) with item code, quantity, supplier, container type, etc.

- A physical board where cards are placed at the moment of consumption (usually with columns representing different suppliers)

- A manual printing system (e.g., Excel, Access, or ERP-generated) to create or reprint cards

Source: IEEE Computer Society

Advantages:

- Extremely simple and visual

- Ideal for small production departments or warehouses with a limited number of items

- Low-cost to implement if IT integrations are not required

Disadvantages:

- Real risk of lost cards (not tracked, requiring manual search/inventory)

- No digital traceability: impossible to know the real-time status of a card without physically checking in the supermarket or on the Kanban board (which suppliers cannot update in real time)

- Manual planning of deliveries on the board (based on lead time)

- No automatic data collection (e.g., consumption or lead time variations), making statistical analysis impossible

- System maintenance (dimensioning, recalculation of cards) requires external tools and usually complex, time-consuming manual updates

- Card printing must be managed with external tools, not integrated into the workflow

- Not suitable for multi-plant contexts or extended supply chains

- ERP orders must be manually created based on the cards placed in the “to be ordered” pocket of the Kanban board

- Goods receipt also requires manual ERP entry

Electronic Kanban: features and benefits

The electronic Kanban preserves the pull logic of the Lean system but introduces:

- Digital cards with unique codes (e.g., QR code or barcode)

- Real-time tracking of card status (available, released, in progress, produced, shipped, etc.)

- A digital Kanban board, always updated and visible to all actors (customers and suppliers)

- Advanced user management to define roles, authorizations, and visibility with just a few clicks

- Automatic scheduling: calculation of delivery dates and visibility in supplier and customer calendars

- Integration with ERP and/or other software (e.g., WMS) to automatically create production, purchase, or sales orders and goods receipt documents

- Error-proof dimensioning wizard

- Automatic maintenance: recalculation of the number of cards (or other parameters) over time thanks to deviation analysis between initial and actual parameters (e.g., consumption variation)

- Configurable templates for card design and print management

- Business intelligence tools to monitor KPIs

Advantages:

- Internal management of printing

- Complete traceability of cards

- Drastic reduction of errors and card loss

- Automatic maintenance and dimensioning

- Real-time collaboration between customer and supplier

- Automatic delivery scheduling

- Automatic notifications

- Data collection and statistical analysis to monitor performance, consumption variations, and propose improvements

- Integration with other software systems

Disadvantages:

- Requires a software platform (subscription or license, such as KanbanRocket)

- Requires willingness to adopt digital/innovative tools

Conclusion: which one to choose?

Paper Kanban is still a valid solution in simple, local contexts with few items to manage.

However, in modern companies operating within complex supply chains or with multiple plants, the electronic version represents the natural evolution.

Thanks to solutions like KanbanRocket, it is possible to digitalize the Kanban system while preserving its Lean principles, but at the same time greatly enhancing its potential.

👉 Discover how our e-Kanban system works and watch the full KanbanRocket Formula video on our Solutions and Pricing page.

comments