Production, Transfer, Purchase and Sales Kanban: differences and use cases

Applying the pull logic correctly according to Lean Production principles requires much more than just hanging cards or setting up racks.

A well-designed Kanban system can extend along the entire supply chain: from internal processes to material handling, up to purchasing and distribution to the final customer.

To structure an effective system, it is necessary to understand which types of Kanban exist, what they have in common, and what operational differences guide the choice of one type over another.

The common logic: what every Kanban shares

Regardless of its application, all Kanban systems are based on common principles that determine how they work.

- A physical container

At the core of every Kanban system there is always a real container. It can be a box, a pallet, or a bin: what matters is that it represents a tangible quantity of material.

- A card that generates a signal

The Kanban card, whether physical or digital, represents the signal that triggers the next action: production, transfer, reorder, or delivery.

It is detached from the container when the latter is emptied, thus starting a new cycle.

- A Kanban board for control

To manage card status, a Kanban board is required. It is a visual management tool that can be physical (a board, a panel) or digital.

KanbanRocket, as an e-Kanban solution, offers a fully configurable electronic board to monitor the material status in real time, even across multiple plants or departments.

- Proper sizing

Each type of Kanban requires accurate sizing, based on:

- Average or statistical consumption (e.g., moving average over a window equal to the lead time, with evaluation at the 95th percentile)

- Lead time for supply, production, or transfer

- Safety lead time to protect against variability and delays

- Quantity per container

- Type of Kanban (Pure, Lot, or Signal)

Inside KanbanRocket, automatic calculation tools are available to dimension each Kanban link correctly.

The differences: when to use different types of Kanban

Once the common elements are clear, it is essential to understand which type of Kanban to adopt depending on the process to be managed.

Production Kanban

Used to trigger internal production of semi-finished goods or components.

- Context: between two departments, or between a work center and a decoupling warehouse (supermarket).

- How it works: the card is released upon consumption and generates a production request.

- Points of attention: lead time must include internal resource availability, setup times, and machine utilization. It is useful to set maximum workload thresholds to avoid card accumulation in queues.

For example, when linking an injection molding department with an assembly department, it may be appropriate to consider lot-type cards to optimize production costs.

With KanbanRocket, it is possible to monitor the real-time status of cards in progress, receive alerts if lead times are not respected, and—thanks to integrations—automatically generate production orders within the ERP system.

Transfer Kanban

Used to manage the physical transfer of materials within the company.

- Typical context: between warehouses and production lines, or between logistics and production departments.

- How it works: the card generates a logistics task for replenishment or transfer.

- Points of attention: layout and material handling routes must be optimized. It is also important to correctly design supermarket areas for picking.

KanbanRocket allows companies to manage internal transfer flows digitally, integrating logistics with production and connecting with existing tools such as WMS.

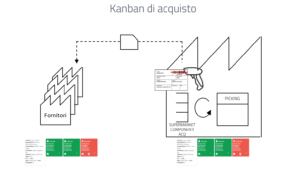

Purchase Kanban

Used to replace manual or MRP-based orders with a pull system driven by actual consumption.

- Typical context: materials purchased from external suppliers (raw materials, components).

- How it works: upon card consumption, a purchase request is generated for the supplier.

- Points of attention:

- The supplier must be trained on the system and involved in defining the basic sizing rules

- Clear agreements must be defined with the supplier (lead time, delivery frequency, minimum lot size, labeling) and formalized in supply contracts

- The supplier must have timely visibility of requests in order to fulfill them (e.g., via the KanbanRocket e-Kanban portal)

- For maximum performance, the supplier should also work in KanbanRocket. For suppliers, using the software is free, which makes integration even more attractive

With KanbanRocket, it is possible to automatically generate purchase orders, track their fulfillment, and create delivery notes (DDT), reducing errors and improving efficiency.

Sales Kanban

Used to manage customer deliveries based on actual consumption.

- Typical context: customer stock management, consignment stock, or automatic replenishment logic.

- How it works: the customer consumes a container, releases the card, and an automatic replenishment is triggered.

- Points of attention:

- Shared visibility between customer and supplier is essential, for example through KanbanRocket boards

- Often codes differ internally from those used by the customer; for this reason, the code transcoding function is useful, allowing each party to use their own codes while maintaining a shared “translation”

With KanbanRocket, companies can manage sales Kanban with shared visibility between customer and supplier, even with different codifications. Integrated with the ERP, the software can automatically create sales orders when the customer consumes a card.

Every Kanban type requires a tailored project

There is no universal rule: every company, flow, and process requires a specific project.

The pull logic only works if it is properly dimensioned, monitored, and maintained.

KanbanRocket supports this complexity with concrete tools for:

- Designing and simulating Kanban links

- Digital management of Kanban cards

- ERP and supplier integration

- Continuous parameter maintenance

Relying on an advanced solution makes it possible to move from the concept of a simple Kanban card to a real Kanban system, fully orchestrated and sustainable.

comments