Lavor Metal: Becoming a Kanban Supplier with Method and Technology

Reading time: 4 minutes

Lavor Metal is a second-generation Italian company founded by Alessandro Zorzi and now led by his son Enea. Since 1999, the company has specialized in cold sheet metal processing for third parties, serving clients in industries such as:

- Professional catering,

- Industrial washing,

- Food service,

- Home appliances,

- Air conditioning and HVAC.

Over the years, Lavor Metal has expanded its client base and technological capabilities, offering laser cutting, punching, robotic bending, welding, painting, and assembly services.

With a project developed in collaboration with Talarys engineers, Lavor Metal has become a Kanban-ready supplier—a strategic partner for clients operating under PULL logic who require consistency, visibility, and fast response times.

More and more structured clients demand that their suppliers operate with a Kanban logic:

– Frequent, regular deliveries

– Based on actual consumption, not forecasts;

– Fast reaction times and low inventory levels.

For a supplier, this is not just about accepting a request but transforming internal organization to respond methodically. Lavor Metal chose a structured path to meet these expectations.

With KanbanRocket, Lavor Metal implemented an integrated e-Kanban system enabling clients to call materials based on real consumption.

Once a Kanban card is released, KanbanRocket connects with the ERP (Factory by Intesi srl) in real time to generate or update a sales order automatically. This automation led to:

- Elimination of manual entry from emails, reducing lead time by 1.5 days on average;

- Avoidance of errors and omissions in order registration.

ERP and MES systems then update KanbanRocket to:

– Ensure timeliness and traceability;

– Automatically update shipping lists and DDTs, which are shared with customers in advance.

Thanks to the structured Kanban service, in few months, Lavor Metal reached:

- +4 new Kanban clients acquired in the first year;

- +16% revenue increase from Kanban-served clients;

- +19.3% delivery punctuality (from 77.7% to over 97%);

- −97% of emergency-related tickets or complaints;

- Over 500 annual orders generated automatically via electronic release.

To meet client lead times, Talarys consultants helped Lavor Metal redesign its internal material organization.

Beyond sales-level Kanban (finished products), Kanban loops were implemented for:

– Semi-finished goods (level 1)

– Critical materials or components (level 2+)

This structure, formalized in supply contracts, helped eliminate stock-outs for key customers.

Each Kanban relationship is supported by:

- A technical supply contract with codes, sizing, replenishment methods, KPIs;

- A clear operational agreement to maintain stable parameters;

- A shared digital portal (KanbanRocket) where clients view card statuses, orders, and withdrawals in real time.

Practical Example: Client SR

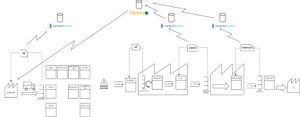

Example of a Value Stream Map implemented at Lavor Metal

Client SR benefited from:

- An integrated Kanban logic across customer orders, production, purchasing, subcontracting;

- Full automation of card releases and system data exchange (Factory, KanbanRocket, Simblux, MES);

- Digitized flows for subcontractors (e.g., painting);

- Improved coordination between technical office, logistics, purchasing, and production.

Lavor Metal shows that becoming Kanban-ready is not just a commercial opportunity but a real competitive advantage. It strengthens client relations, reduces manual tasks, and lowers operational risk.

With the Talarys team and the KanbanRocket Formula, any supplier can begin this journey in a gradual, structured, and measurable way—to satisfy demanding clients and raise their own operational and commercial maturity.

comments